Cooling of Transformer is the process by which heat generated in the transformer is dissipated or treated to the safe value. This is achieved by various cooling methods of transformer available.

The major factor for the generation of heat in the transformer is the various losses like hysteresis, eddy current, iron, and copper loss. Among all the various losses the major contributor of the heat generation is the copper loss or I2R loss.

Contents:

- Air Natural (AN)

- Air Forced (AF) or Air Blast

- Oil Natural Air Natural (ONAN)

- Oil Natural Air Forced (ONAF)

- Oil Forced Air Forced (OFAF)

- Oil Natural Water Forced (ONWF)

- Oil Forced Water Forced (OFWF)

If the temperature of the transformer will continue to increase rapidly, it will result in the degradation of the insulation used in the transformer resulting in the damaging of the various parts and hence the failure of the transformer. Thus, proper removal or treatment of heat is necessary for the efficient working, longer life and higher efficiency of the transformer.

The various coolants used for the cooling purpose of the transformer are air, synthetic oils, mineral oils, gas, water.

Basically, there are two types of transformer one is the dry type, and another one is oil-immersed type. For the cooling of transformers, the following cooling methods listed below are used.

- Air Natural

- Air Blast or forced

- Oil Natural Air Natural

- Oil Natural Air Forced

- Oil Forced Air Forced

- Oil Natural Water Forced

- Oil Forced Water Forced

Methods of Cooling of Transformer

The detailed description of cooling methods, one by one is given below.

Dry Type Transformer is cooled by the following two methods given below:

Air Natural (AN)

By Air Natural method the generated heat in the transformer is cooled by the circulation of natural air. When the temperature of the transformer becomes higher as compared to the temperature of the surrounding air, thus by the process of natural convection, heated air is replaced by the cool air. This method is also known as a self-cooled method. This method is used for cooling the smaller output transformer rating that is up to 1.5 MVA.

Air Forced (AF) or Air Blast

In this method, the heat generated is cooled by the forced air circulation method. With the help of fans and blowers, high velocity of air is forced on the core and the windings of the transformer. As the temperature inside the transformer goes beyond the standard safe level, an alarm is activated, and the fans and blowers are switched ON automatically. This method is used for transformer rating up to 15MVA.

Oil-immersed type transformer is cooled by the oil-air cooling method and oil-water cooling method.

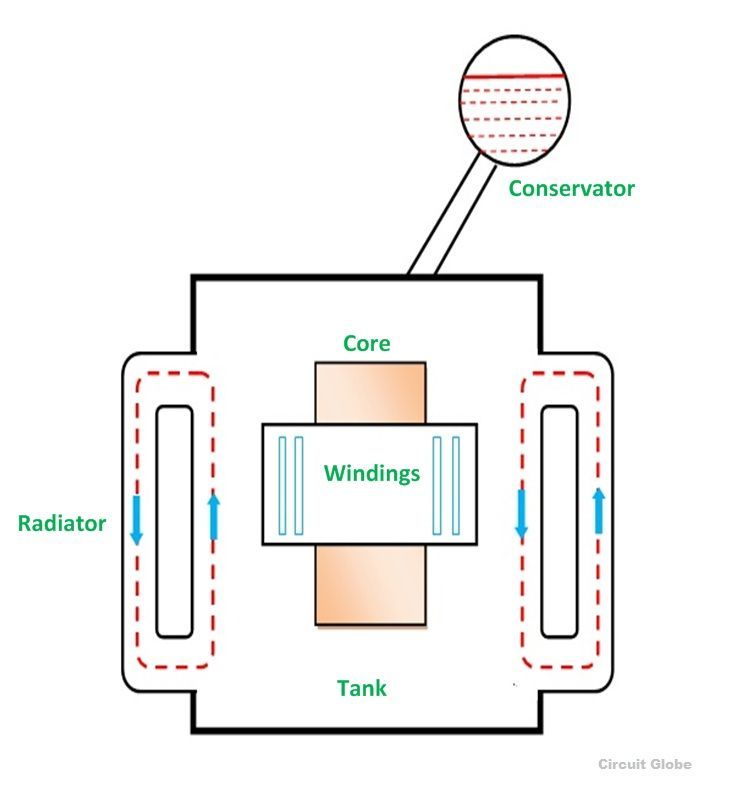

Oil Natural Air Natural (ONAN)

Natural convection process is used for this type of cooling. The assembly of the core and windings are placed in the oil-immersed tank. As the core and the windings heat up the temperature of the oil in the transformer rises. As a result, the oil moves upward and flows from the upper portion of the transformer tank. This hot oil dissipates heat in the air by natural convection and conduction process, the oil gets cooled by the circulation of natural air and passes through the radiator again for the use of the transformer. This type of cooling is used for the transformer rating up to 30 MVA.

Oil Natural Air Natural Cooling of Transformer Oil Natural Air Forced (ONAF)

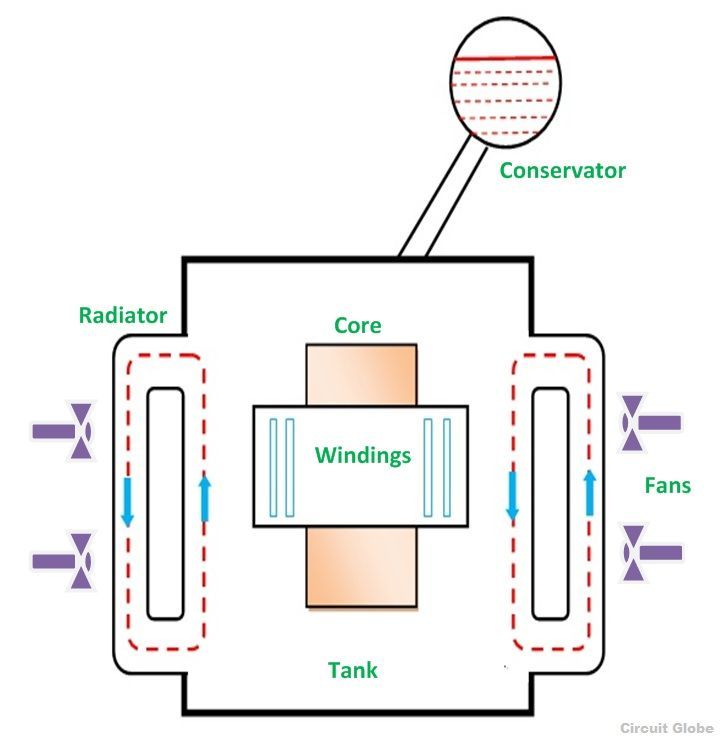

ONAF method is used for the cooling of the transformer of rating up to 60 Mega volts ampere. As discussed above that in ONAN method, the dissipation of heat is taking place by the convection process in which air is naturally circulated to cool down, but in this type, the forced air is used for the purpose of cooling the transformer.

The cooling of oil will be faster if the area of the tank of the transformer is increased finally, which result in the increase in heat dissipation level. As the fans and blowers are installed, a high velocity of air is forcefully applied to the radiator and cooling towers which will help in cooling oil more quickly and efficiently.

Its cost is higher as compared to another process where the circulation of oil and air is done naturally because a fan and blowers are attached as extra cooling equipment, in this method.

Oil Natural Air Forced Cooling of Transformer Oil Forced Air Forced (OFAF)

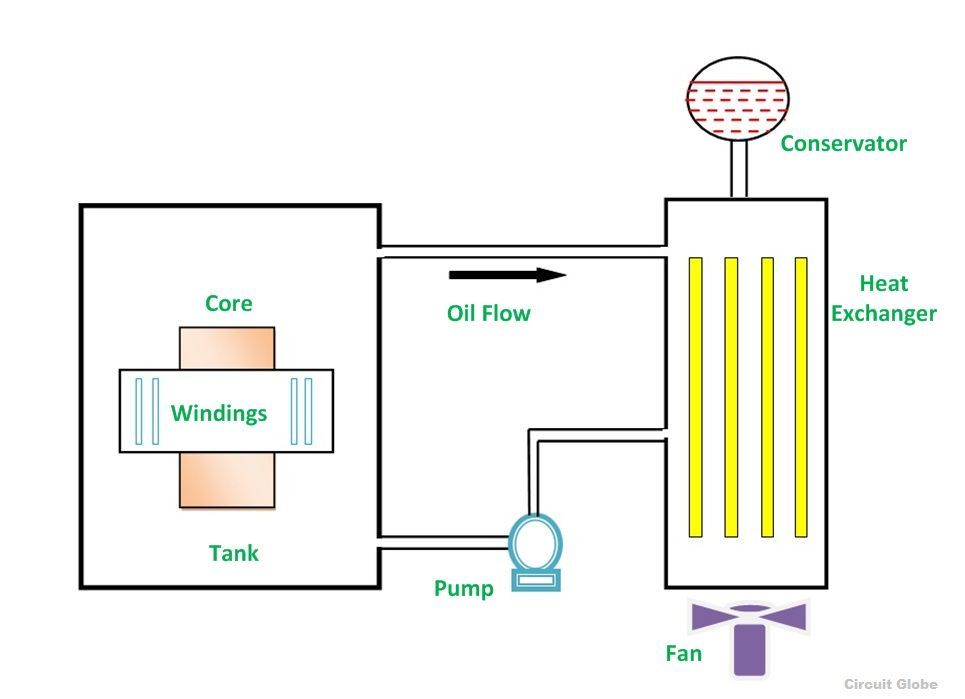

As the name itself says that both the oil and the air are applied by force for cooling of a transformer. The Heat Exchanger is installed through which hot oil is circulated with the help of a pump. Air is forced to pass on the heat exchanger with the help of high-speed fans.

This method is similar to ONAN, as when there is low load on the transformer the cooling is done by a simple ONAN method. However, as soon as the load is increased, the generated heat will also be more and therefore the sensor gives an alarm that the dissipation of heat has exceeded the safe value and as a result, the fans and pumps are switched on automatically. Thus, the cooling takes place by OFAF method.

Oil Forced Air Forced Cooling of Transformer Oil Natural Water Forced (ONWF)

In Oil Natural Water Force cooling method, the transformer core and the windings are immersed in the oil tank. A radiator is installed outside the tank, as the temperature rises and the oil heats up and moves upward, the heat is dissipated by the natural process of convection and oil is passed through the radiator, but the water is pumped and passed through the heat exchanger for cooling of the oil.

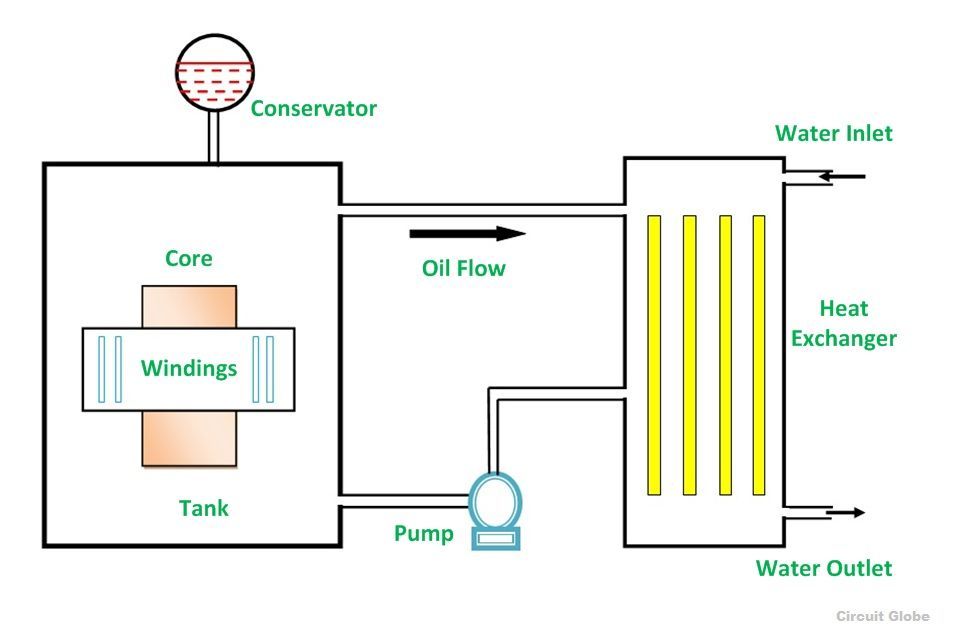

Oil Forced Water Forced (OFWF)

A heat exchanger is installed through which both oil and water are passed with the help of a pump. The level and pressure of the oil are always kept higher than that of water so that if any leakage occurs in the system the oil mixes with the water, but water does not get mixed up with the oil.

This type of method is suitable for large capacity of the transformer having rating as several hundred MVA or where banks of transformers are installed. Mainly this type of cooling is done for the transformer installed at the hydropower plant.

Here we have completed the discussion on cooling of the transformer.

very informative.

excellent explanation….

thanks

Very good explanation

Wow! perfect description

So good information!

Interesting

Thanks for sharing