Definition: Oil filled cable is defined as the cable in which low viscosity oil is kept under pressure either within the cable sheath itself or a containing pipe. The oil in the cable filled the voids in the oil impregnated paper under all conditions of varying loads. In the past, over the years mineral oils are used but recently alkylates (linear decyl benzene and branched nonyl benzene) become popular because of their low viscosity and their ability to absorb water vapours liberated during ageing of cellulose.

Oil filled cables are used for long power transmission or in placed where aerial cable are impracticable to used like sea, underground hydroelectric plant or in power substations having water obstacles.

Advantage of Oil Filled Cables

The pressure in the cable is sustained by connecting the oil channel of the cable to the oil tank. For maintaining the pressure, the oil channel is placed far away from the oil reservoir. The oil pressure reduces the formation of voids in the insulator. Oil filled cables have the following advantages over solid cables:

- The oil filled cables have greater operating dielectric stress.

- Such type of cable has greater working temperature and greater current carrying capacity.

- Oil filled cable has better impregnation as compared to solid cable.

- In oil-filled cable, impregnation is possible, even after sheathing.

- In such type of cable, there is no void formation.

- The size of oil-filled cable is small as compared to solid filled cables because their dielectric thickness is less.

- In oil-filled cable, the defect can easily be detected by oil leakage.

Types of Oil Filled Cable

Oil filled cables are mainly classified into three types. These are;

- Self-contained circular type oil cable

- Self-contained Flat type cable

- Pipeline cable

Self-Contained Oil-filled Cable

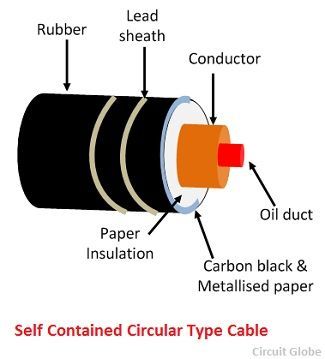

These cables have oil ducts full of oil. The oil is kept under pressure, and their strength is 180 kV/cm. In this type of cable, all the free space between the core is available for oil flow. The oil in the cables filled the free spaces of the insulations and hence increase the strength of the insulations.

The cross section area of conductor used for such type of cable is nearly 150-180 sq mm, and it is made up of tin. The diameter of the oil ducts used in such cable is approximately 12 mm. Such type of cable is mostly used for voltage up to 110-220 kV.

The cross section area of conductor used for such type of cable is nearly 150-180 sq mm, and it is made up of tin. The diameter of the oil ducts used in such cable is approximately 12 mm. Such type of cable is mostly used for voltage up to 110-220 kV.

Advantages of self-contained oil filled cables

Self-contained oil filled cable have following advantages as compared to other oil-filled cables:

- The size of the conductor is small in self-contained oil filled cable because it contains oil ducts.

- Such type of cable is easy to install.

- Their cost is less as compared to other oil filled cable.

- In self-contained oil filled cables, no pumps are required, only oil tanks are to be used.

Such types of oil-filled cables are very widely used for the merits mentioned above.

Flat Type Oil Filled Cable

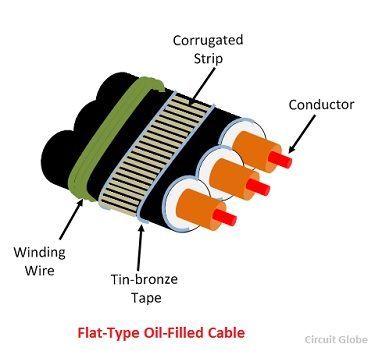

In such type of cable three insulated cores are placed together horizontally. There is no filter material, and space is filled up with oil under pressure. The flat sides of the lead sheath are the strength with hard metallics tapes or bands and winding wires. The supporting bands are made fluted to make the cable more flexible.

When the cable is loaded, their temperature rises and the oil expands due to which the flat side of the sheath is deformed slightly. On decreasing, the load oil contracts and deflections are reduced due to the presence of resilient bands. Thus the voids formation in the dielectric during cooling is minimised.

Oil storage tank is placed along the cable route at suitable intervals to allow for thermal expansion and contraction. On loading, the cable heat is produced, and oil is driven by the cable in the oil storage tanks and vice versa. Thus, the creation of voids is avoided.

Oil storage tank is placed along the cable route at suitable intervals to allow for thermal expansion and contraction. On loading, the cable heat is produced, and oil is driven by the cable in the oil storage tanks and vice versa. Thus, the creation of voids is avoided.

Pipes Types Oil Filled Cables

A pipe type oil filled cable consists of three separate paper insulated screen cores installed in a steel pipe. The pipe is filled with insulation oil kept at a pressure of 1.38×106 to 1.725×106 N/M2. The high-pressure oil prevents the formation of voids. It also removes heat from the cable. In this type of cable, the conductor oil duct is not required.

This is very helpful..thanks

I would like to learn more about the pressure tank on oil filled cable