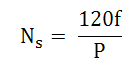

Variable Frequency Control is a method that is used to control the speed of an induction motor. The synchronous speed and therefore, the speed of the motor can be controlled by varying the supply frequency. The synchronous speed of an induction motor is given by the relation shown below:

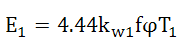

The EMF induced in the stator of the induction motor is given by the equation shown below.

Therefore, if the supply frequency is changed, induced EMF will also change to maintain the same air gap flux. The terminal voltage V1 is equal to the induced EMF E1 if the stator voltage drop is neglected.

In order to minimize the losses and to avoid saturation, the motor is operated at rated air gap flux. This condition is obtained by varying the terminal voltage with frequency so as to maintain the (V/f) ratio constant at the rated value. This type of control is known as Constant Volts Per Hertz. Thus, the speed control of an induction motor using a variable-frequency supply requires a variable voltage power source. The variable-frequency supply is obtained by the following converters.

- Voltage source inverter

- Current source inverter

- Cyclo converter

An inverter converts a fixed voltage DC to a fixed or variable voltage AC with variable frequency. Cyclo converter converts a fixed voltage and fixed frequency AC to a variable voltage and variable AC frequency.

The variable frequency control allows good running and transient performance to be obtained from a cage induction motor. Cyclo converter controlled induction motor drive is suitable only for large power drives and to get lower speeds.