A three-phase Induction Motor is Self Starting. When the supply is connected to the stator of a three-phase induction motor, a rotating magnetic field is produced, and the rotor begins rotating and the induction motor starts. At the time of starting, the motor slip is unity, and the starting current is very large.

The purpose of a starter is not to just start the motor, but it performs the two main functions. They are as follows:

- To reduce the heavy starting current,

- To provide overload and under-voltage protection.

The three-phase induction motor may be started by connecting the motor directly to the full voltage of the supply. The motor can also be started by applying a reduced voltage to the motor. The torque of the induction motor is proportional to the square of the applied voltage. Thus, greater torque is exerted by a motor when it is started on full voltage than when it is started on the reduced voltage.

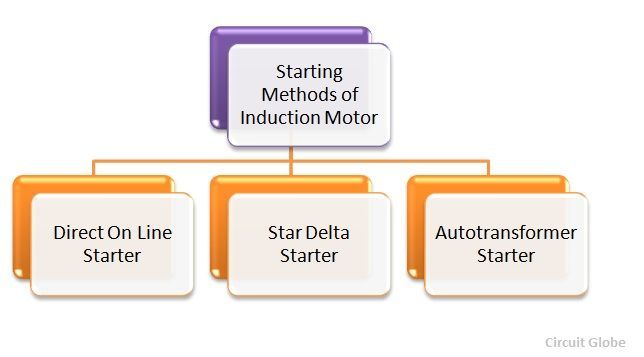

There are three main methods of Starting of Cage Induction Motor. They are as follows:

Direct on-line starter

The direct on-line starter method, of an induction motor, is simple and economical. In this method, the starter is connected directly to supply voltage. By this method, small motors up to 5 kW rating are started to avoid the supply voltage fluctuation.

Star delta starter

The star delta starter method of starting three-phase induction motors is very common and widely used among all the methods. In this method, the motor runs at delta-connected stator windings.

Autotransformer starter

The Autotransformer is used in both types of connections, i.e., either star connected or delta connected. The autotransformer is used to limit the starting current of the induction motor.

The above three starters are used for the cage rotor induction motor.

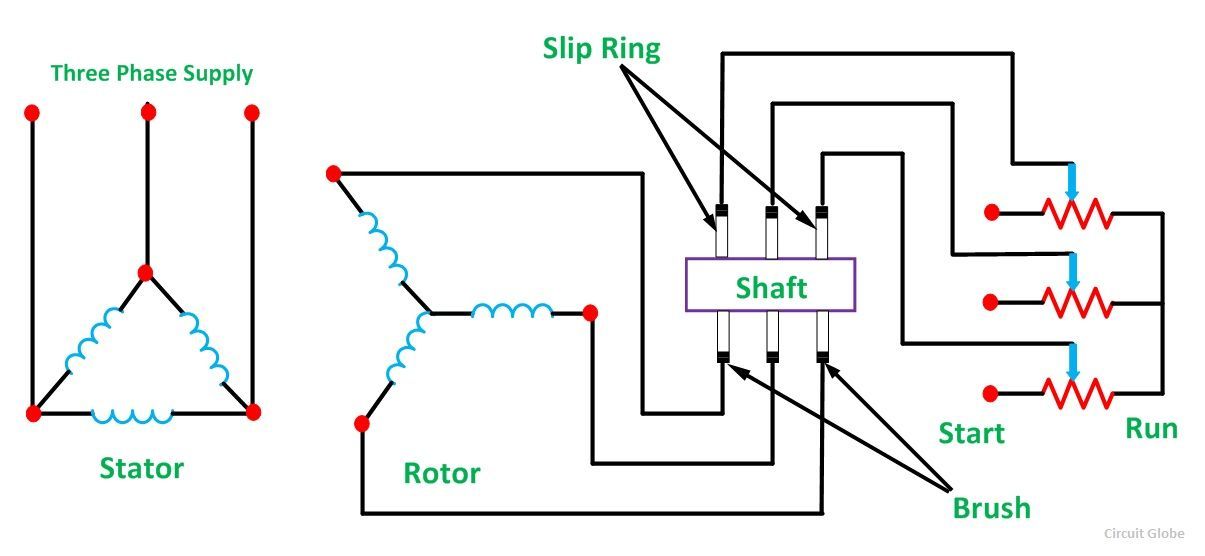

Slip Ring Induction Motor Starter Method

In the Slip Ring Induction Motor starter, the full supply voltage is connected across the starter. The connection diagram of the slip ring starter induction motor is shown below:

Full starting resistance is connected and thus the supply current to the stator is reduced. The rotor begins to rotate, and the rotor resistances are gradually cut out as the speed of the motor increases. When the motor is running at its rated full load speed, the starting resistances are cut out completely, and the slip rings are short-circuited.

Full starting resistance is connected and thus the supply current to the stator is reduced. The rotor begins to rotate, and the rotor resistances are gradually cut out as the speed of the motor increases. When the motor is running at its rated full load speed, the starting resistances are cut out completely, and the slip rings are short-circuited.

Great content+easy to understand

nicely article sir

good information sir

Nice article

thanks

awesome content and easy language.

Thanks sir

Very informative.

Well brief explanation

A great summary.