The motors which can be used with a single-phase AC source, as well as a DC source of supply and voltages, are called Universal Motor. It is also known as Single Phase Series Motor. A universal motor is a commutation-type motor. If the polarity of the line terminals of a DC series motor is reversed, the motor will continue to run in the same direction.

The direction is determined by both field polarity and the direction of current through the armature. As torque is proportional to the flux and the armature current. Let the DC series motor be connected across a single-phase AC supply. Since the same current flows through the field winding and the armature winding. The AC reversal from positive to negative or vice versa will affect the field flux polarity and the current direction through the armature.

The direction of the developed torque will remain positive, and the direction of the rotation will be as it was before. The nature of the torque will be pulsating, and the frequency will be twice that of line frequency as shown in the waveform below.

Thus, a universal motor can work on both AC and DC. However, a series motor that is mainly designed for DC operation if works on single-phase AC supply suffers from the following drawbacks:

- The efficiency becomes low because of hysteresis and eddy current losses.

- The power factor is low due to the large reactance of the field and the armature windings.

- The sparking at the brushes is in excess.

In order to overcome the above following drawbacks, certain modifications are made in a DC series motor so that it can work even on the AC current. They are as follows:

- The field core is made up of the material having a low hysteresis loss. It is laminated to reduce the eddy current loss.

- The area of the field poles is increased to reduce the flux density. As a result, the iron loss and the reactive voltage drop are reduced.

- To get the required torque the number of conductors in the armature is increased.

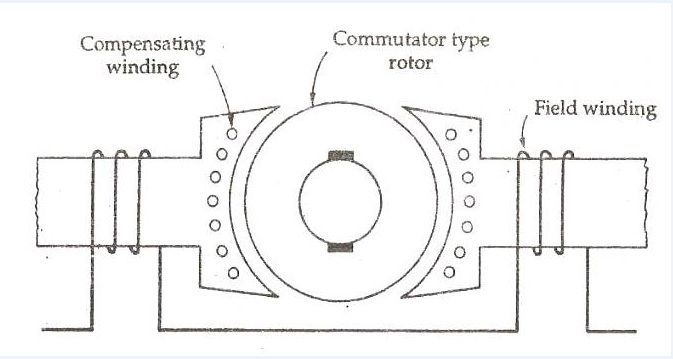

A compensating winding is used for reducing the effect of the armature reaction and improving the commutation process. The winding is placed in the stator slots as shown in the figure below:

The series motor with the compensated winding is shown in the figure below:

The series motor with the compensated winding is shown in the figure below:

The winding is put in the stator slot. The axis of compensating winding is 90 degrees with the main field axis. The compensating winding is connected in series with both the armature and the field, hence, it is called Conductively compensated.

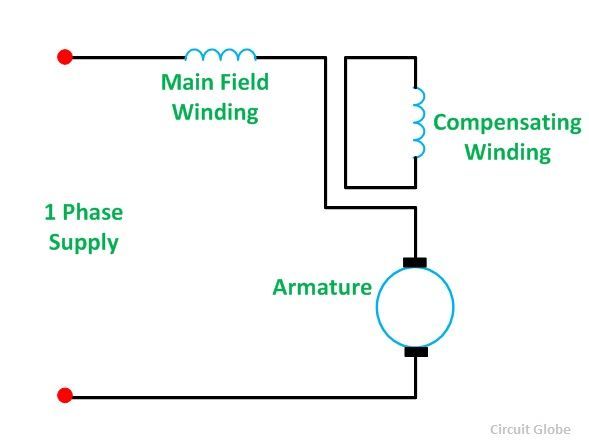

If the compensating winding is short-circuited, the motor is said to be inductively compensated. The connection diagram is shown below:

The construction of the universal motor is the same as that of the series motor. In order to minimize the problem of commutation, high resistance brushes with increased brush area are used. To reduce Eddy current losses the stator core and yoke are laminated. The universal motor is simple and less costly. It is used usually for ratings not greater than 750 W.

The characteristic of the Universal motor is similar to that of the DC series motor. When operating from an AC supply, the series motor develops less torque. By interchanging connections of the fields with respect to the armature, the direction of rotation can be altered.

Speed control of the universal motors is obtained by solid-state devices. This motor is most suitable for applications requiring high speeds. Since the speed of these motors is not limited by the supply frequency and is as high as 20000 rpm.

Applications of Universal Motor

The Universal motor is used for purposes where speed control and high values of speed are necessary. The various applications of the Universal Motor are as follows:

- Portable drill machines.

- Used in hairdryers, grinders, and table fans.

- A universal motor is also used in blowers, polishers, and kitchen appliances.

This is all about Universal Motors.

Thanks ….